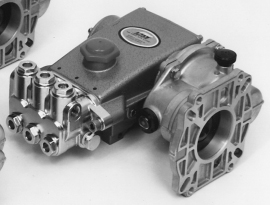

CAT Pump 8058 Direct Drive Gearbox Helical -1-1/8″ Shaft, Gearbox Pump: 51G118, 58G118 Used on Models 51 and 58 Pump.

The CAT Pump 8058 Direct Drive Gearbox Features:

- Polished solid ceramic plungers last long and resist abrasion.

- Triplex plunger design providing low pulsation and quiet operation.

- Internally lubricated and cooled packings for extended life.

- No pulley selection or adjustment for quick, easy gas engine mounting.

- Totally sealed housing providing independent

- gearbox lubrication for maximum service life. Hardened steel helical design gears for smooth, quiet operation.

- Multiple engine shaft and flange options for flexibility.

The CAT Pump 8058 Direct Drive Gearbox has the following specifications:

- Gear Ratio ………………………… 2.0384 to 1 (2.0384 to 1)

- Mounting Face…………………… 6-1/2″ (165 mm)

- Engine Shaft Diameter……………………………………….. 1″ (25.4 mm)……………………………………….. 1-1/8″ ( 28.5 mm)

- Engine Shaft Length…………… 3-1/4″ (82.6 mm)

- Gearbox Capacity………………. 10 oz. (0.30 L)

- Weight 8051, 8058, 8061, 8065, 8068…. 4.2 lbs. (1.90 kg) 8071, 8078 ………………………… 7.5 lbs. (3.40 kg)

- Dimensions……………………….. 6.42 x 4.53 x8.19″ (163x115x208 mm)

- Flow…………………………………. 5.0 GPM (19 L/M)

- Pressure Range ………………… 100 to 2500 PSI (7 to 175 BAR)

- Inlet Pressure Range………….. Flooded to 60 PSI (Flooded to 4 BAR)

- Maximum Pump RPM…………. 1570 RPM (1570 RPM)

- Maximum Engine RPM……….. 3200 RPM (3200 RPM)

- Bore…………………………………. 0.708″ (18 mm)

- Horsepower-Electric …………… 8.6 HP (8.6 HP)

- Stroke ………………………………. 0.669″ (17 mm)

- Pump Crankcase Capacity….. 25 oz. (0.75 L)

- Weight ……………………………… 30.7 lbs. (13.9 kg)

- Dimensions with .B…………….. 13.58 x 10.75 x 8.19″ (345 x 273 x 208 mm)

- See Models 53, 58, 55, 51 data sheet for pump information.

List Price: $685.00

Our Price: $685.00

Sale Price: $600.00

You save $85.00!

![]()

Availability:: available for order

Product Code: 8058

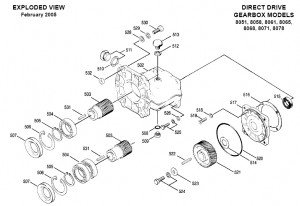

1. Completely drain lube from the direct drive gearbox housing.

2. Remove the four HHC screws which fasten the direct drive gearbox to the engine and separate gearbox and pump from engine.

3. Remove the four HHC screws which fasten the direct drive gearbox to the bearing cover flange and separate gearbox housing from pump.

4. Place gearbox housing on work surface with seal facing up.

5. Remove pinion oil seal by inserting screwdriver between pinion gear and inner lip of seal and pry out. Seal will be damaged and must be replaced.

6. Remove large retaining ring in groove below the pinion oil seal using retaining ring pliers and set aside for re-use.

7. Remove the pinion gear and bearing. Turn direct drive gearbox housing over onto engine mount flange surface. Bearing is pressed into position so it is necessary to press pinion and bearing out from rear. Set gearbox housing aside.

8. Remove bearing from pinion gear. Using reverse pliers remove retaining ring from groove on pinion gear and press bearing from pinion. Set aside pinion, bearing and retaining ring.

9. Remove hex machined retaining screw, lockwasher and flat holding washer from center of helical drive gear on pump shaft.

10. Slip helical drive gear from crankshaft.

11. Remove key from keyway in pump crankshaft. At this point the direct drive gearbox has been disassembled. Now begin examination of the gearbox parts for wear and reassembly. While the gearbox is in this state of disassemble, it is advisable to examine your pump for any indication of drive-end wear. If any of the following conditions are present, removal of the bearing cover flange is necessary. Only trained technicians should service drive end.

– Leakage between bearing cover flange and pump crankcase.

-Evidence of water in pump crankcase.

-Evidence of water in gearbox crankcase.

NOTE: If removal of bearing cover flange is necessary, completely drain oil from crankcase of pump.REMOVING BEARING COVER FLANGE

1. Remove the HSH screws, lockwashers and washers from bearing cover flange.

2. Tap flange with soft mallet to separate from pump crankcase.

3. Examine pump bearing and replace if worn.

4. Examine oil seal in bearing cover flange and replace if worn.

5. Examine gasket on outside of bearing cover flange and replace if cut or cracked.

6. Examine o-ring on inside outer groove of bearing cover flange and replace if cut or worn. If further pump servicing is needed, refer to your pump service manual, and Tech Bulletin 035 on “Servicing Crankcase Section”.REPLACING BEARING COVER FLANGE

1. Line up the four holes and mount gasket on outside of bearing cover flange. Note: Models 56, 59, 60 and 70 have dual bearings and eight screws.

2. Press new seal into bearing cover flange after exercising caution not to cut seal on keyway edge.

3. Line up the inside mounting holes on bearing cover flange with the holes on the pump. Keep the two outer “flanged” mounting holes to the top rear and lower front.

4. Apply Loctite-242 to the threaded area of screws before replacing. Torque per chart.REASSEMBLY of the CAT Pump 8058 Direct Drive Gearbox

1. Insert key into pump crankshaft keyway until flush with end of shaft.

2. Examine helical drive gear teeth for wear and replace if necessary. Line up keyway on gear with pump shaft keyway and key and slide onto shaft.

3. Install flat holding washer, lockwasher and retaining screw onto shaft and torque per chart.

4. Examine gearbox oil gauge and oil drain plug for any evidence of leaking and replace o-ring and gasket if necessary.

5. Examine pinion bearing for wear and replace if necessary.

6. Examine pinion gear teeth for wear and replace if necessary.

7. Press bearing over pinion gear until seated on shoulder. (Models with dual bearings; press first bearing on until seated; then second bearing until seated up to first bearing.)

8. Install retaining ring on pinion gear and snap into groove.

9. Insert pinion and gear assembly into gearbox housing and press into position until seated on shoulder. Groove for large retaining ring must be visible.

10. Insert large retaining ring into pinion bearing housing and snap into groove.

11. Lubricate I.D. and O.D. of new pinion oil seal. Place oil seal at mouth of pinion bearing housing with garter spring facing down. Carefully press seal into position until seated on retaining ring. Keep seal square in position to avoid inner lip hanging up on pinion gear edge.

12. Rotate pinion gear so keyway is up. Mount assembled gearbox housing onto pump shaft with helical drive gear. NOTE: Carefully match gear teeth and line up mounting holes. Place engine mounting flange in forward position.

13. Install the screws to fasten gearbox to bearing cover flange. Torque per chart.MOUNTING the CAT Pump 8058 Direct Drive Gearbox ONTO ENGINE

1. Rotate crankshaft of engine until keyway is at top.

2. Insert key into keyway and generously apply Loctite 76764 antiseize lubricant to engine shaft.

3. Line up keyway of pinion gear and engine shaft and carefully slip gearbox onto engine shaft until flush with engine face. Install four hex machined screws. Torque per chart. NOTE: Due to varying engine shaft lengths it may be necessary to install a small spacer on each of the four (4) hex machined screws between gearbox flange and engine face.

4. Before starting operation, fill gearbox housing to oil gauge dot with 80-90 weight gear lube and fill crankcase of pump to oil gauge dot with CAT PUMPS Special Premium Grade Non-detergent Oil.FIELD CONVERSION FROM STANDARD PUMP

To convert from a standard pump to a direct drive gearbox pump, remove the existing bearing cover, gasket and four combination head screws. Replace with new direct drive gearbox bearing cover flange, gasket, four lockwashers and new hex socket flat head screws. The bearing for the 51, 56, 58, 59 and 60 pumps is a tapered roller bearing with outer race. Remove the standard bearing cover from the pump. Remove outer race from bearing cover by gently pounding on work surface to unseat. Then use a bearing puller tool to pull race from bearing cover. Next press outer race into gearbox bearing cover flange. Be certain race is completely seated in flange before mounting onto pump.