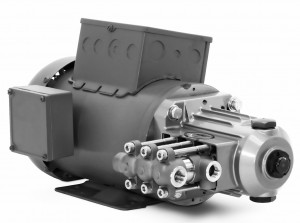

The AR North America RMW2.2G24-ST features a 7/8″ hollow shaft, operates at 3400 RPM, and has a max PSI of 2400. The inlet and outlet tubes are short in this version of the pump. Manifold is made from precision die cast aluminum.

The matching flange on this Annovi reverberi RMW2.2G24-ST pressure washer pump provides convenient connection to most 3/4” shaft 1.1 – 5.5 HP engines. The hollow shafted pump includes a built-in pressure control valve, and chemical injection system.

Annovi Reverberi / AR North America RMW2.2G24-ST, RMW 22G24-ST, RMW 2.2G24-ST Vertical Radial-Axial series replacement pump (Mounts under the engine)

We do not have any mfg cross reference information available. However, RMW pumps fit most vertical engines (pump under the motor) with a 7/8″ straight keyed shaft.

Special Note: Use AR64545 Oil in this Annovi reverberi RMW2.2G24-ST pressure washer pump. Do NOT change oil. Use oil only to add if low. This oil is a specially formulated synthetic with special additives for the demands of this Annovi reverberi RMW2.2G24-ST pressure washer pump. No other oil is factory approved for these pumps, and could result in Annovi reverberi RMW2.2G24-ST pressure washer pump failure.

All positive displacement Annovi reverberi RMW2.2G24-ST pressure washer plunger pumps must have a safety relief valve installed on the discharge side of the pump, this valve could be either an unloader or regulator and must be of adequate flow and pressure for the pump. (This Annovi reverberi RMW2.2G24-ST pressure washer pump has an unloader already built in). Adequate protective guards must cover all moving parts. Perform routine maintenance on the pump and components. Use only components that are rated for the flow and pressure of the pump, this would include hose, fittings, safety valves, spray guns etc.

Special Features of the Annovi reverberi RMW2.2G24-ST pressure washer pump

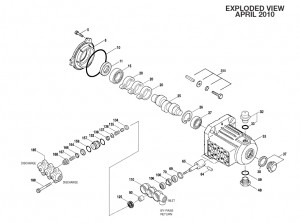

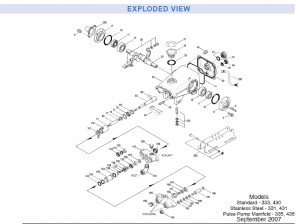

Wet End of the Annovi reverberi RMW2.2G24-ST pressure washer pump:

Manifold: Forged Brass: Strength and no porosity – long life. Higher hydrostatic pressures – safety.

Unloader: Integral trap pressure, fixed chemical injector. Simple repair using a cartridge replacement kit.

Bolts: Three bolts, 6mm grade 8.8.

Valves for the Annovi reverberi RMW2.2G24-ST pressure washer pump:

Ultra Form Cages: Durable, strong, and long life. Poppets and Spring: 303 series stainless steel.

Valve Seat: Brass with an external sealing o-ring on both inlet and discharge valves.

Valve Caps: Machined brass for greater strength.

Packing and Plungers: Dual seal system. High Pressure Packing and Low-Pressure

Seals: “U” cup double lip Buna-N for a good positive seat.

Support and Guides: Special anti-wear plastic, 1-piece construction to assure proper plunger alignment, maximize packing and seal life and prevent plunger wear and damage.

Plungers on this Annovi reverberi RMW2.2G24-ST pressure washer pump: Solid hardened stainless steel, strong and durable.

Drive End

Bearings: Oversized ball bearing stabilizes the crankshaft and one needle style thrust bearing absorbs the plunger load and assures long radial plate life.

Crankcase: Precision die-cast, with cooling fins for maximum heat dissipation. The housing retains the crankshaft bearing, oil seal and rear wobble plate bearing support washer.

Crankshaft/Wobble Plate: Precision die-cat to assure proper stroke, duration and alignment.

Oil Seals and O-rings: All are constructed of Buna-N rubber. The oil seals have stainless steel garder springs to assure constant tension on the sealing surface.

Oil Capacity: 2.2 oz.

Ports:

Inlet Port: Is supplied with a standard brass garden hose connection with inlet strainer.

Discharge Port: Is supplied with 3/8”M connection.

Accessory Ports: All Annovi reverberi RMW2.2G24-ST pressure washer pump models have a 1/4”F port on the inlet side of the manifold.

Extra Features of the Annovi reverberi RMW2.2G24-ST pressure washer pump:

Dyno Proven: All Annovi reverberi RMW2.2G24-ST pressure washer pump are dyno tested to assure the theoretical design meets the actual design.

Valve Design: Each Annovi reverberi RMW2.2G24-ST pressure washer pump series has a valve design that optimizes its highest efficiency.

Wet End Repair: Very simple no special tools required.

Design: Using advanced fluid handling design programs. Overall Annovi reverberi RMW2.2G24-ST pressure washer pump efficiency is increased.

The Annovi reverberi RMW2.2G24-ST pressure washer pump Features:

- NOTE: This Annovi reverberi RMW2.2G24-ST pressure washer pump DOES NOT fit Karcher units using a hex head bolt to drive the pump.

- Fits most homeowner type vertical pressure washers

- Note: This Annovi reverberi RMW2.2G24-ST pressure washer pump is Back Mounted and turned 180º

- Note: This Annovi reverberi RMW2.2G24-ST pressure washer pump has short inlet and outlet tubes

- Annovi reverberi RMW2.2G24-ST pressure washer pump comes with oil

- Stainless steel plungers

- Aluminum manifold w/aluminum valve plugs

- Outlet Port: 22mm (Twist Connect)

- Inlet Port: 3/4″ FGH (garden hose)

- Maximum Horsepower Requirements: 5.0 GHP

- Built In unloader and chemical injector

- Engine shafts longer that 2” will require spacers or washers

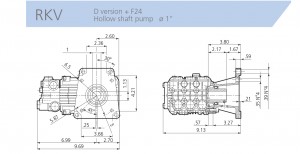

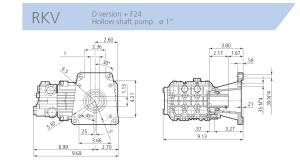

Technical Specifications of the Annovi reverberi RMW2.2G24-ST pressure washer pump are:

- Max Flow (in GPM): 2.2

- Max Flow (in L/Min): 8.3

- Max Pressure (in PSI): 2400

- Max Bar: 166

- Power EBHP: 3.6

- Bore Dia: 12mm

- Stroke: 8.3mm

- Crankshaft ID Stamp: 5

- Pump Speed (in RPM): 3400

- Shaft Diameter: 7/8″ hollow

List Price: $244.01

Our Price: $157.21

You save $86.80!

Availability:: available for order

Product Code: RMW2.2G24-ST

Annovi Reverberi Pressure Washer Pump

PRICE SUBJECT TO CHANGE. PRICE VALID ON THIS Annovi reverberi RMW2.2G24-ST pressure washer pump 11/8/2011