| BE Water Pump WP-2070S | BE Water Pump WP-3070S | ||||

|

|

||||

|

|

||||

| BE Water Pump 2″ – 7.0 – 158GPM: Maximum Pressure of 158PSI With a Aluminum Volute Carbon Ceramic Mechanical Seal With a Cast Iron Impelller Total Head Lift of 82′ Suction Head Lift of 35′Blog for this BE Water Pump Click Here. |

BE Water Pump 3″ – 7 – 264GPM: Maximum Pressure of 37PSI With a Aluminum Volute Carbon Ceramic Mechanical Seal With a Cast Iron Impelller Total Head Lift of 85′ Suction Head Lift of 26′ |

||||

| BE Water Pump WP-2065CM |  |

||||

|

|||||

|

|||||

| BE Water Pump 2″ – 7 – 158GPM: Maximum Pressure of 35PSI With a Aluminum Volute Carbon Ceramic Mechanical Seal With a Cast Iron Impelller Total Head Lift of 82′ Suction Head Lift of 26′ |

|||||

Aug 26 2011

Got Flooding? Get A Water Pump to remove that water from your basement…

Permanent link to this article: https://etscompany.com/wordpress/2011/08/26/got-flooding-get-a-water-pump-to-remove-that-water-from-your-basement/

Aug 26 2011

Hurricane Warnings? Get Your Portable Generator Now.. 3 to choose from! From ETS Co.

| PORTABLE GENERATOR MNBE-VI-3000 | PORTABLE GENERATOR MNBE-VI-6500 | ||||

|

|

||||

|

|

||||

| MNBE-VI-3000 PORTABLE GENERATOR | Portable generator with 6500 watts max AC output, 5500 watts continuous AC output. | ||||

| PORTABLE GENERATOR MNBE-VI-9000 |  |

||||

|

|||||

|

|||||

| DC output of 12V and 8.3A A reliable Electric Start Starting System Three 120V 20A GFCI Duplex Receptacle and Two 120V Twistlock Receptacles 120V/240V Fuel Tank Capacity of 25L and a max runtime of 6.5Hrs at full load Noise level at 7m of 78db |

|||||

Permanent link to this article: https://etscompany.com/wordpress/2011/08/26/hurricane-warnings-get-your-portable-generator-now-3-to-choose-from-from-ets-co/

Aug 26 2011

Storms coming to the east coast, be ready with a Water Pump from ETS Co…

The BE Water Pump 2″ – 7.0 – 158GPM Features:

Maximum Pressure of 158PSI

With a Aluminum Volute

Carbon Ceramic Mechanical Seal

With a Cast Iron Impelller

Total Head Lift of 82′

Suction Head Lift of 35′

- Engine Powerease 7HP OHV

- Pump Type Centrifugal, Aluminum

- Discharge Capacity 158GPM

- Suction Port Diameter 2″ MNPT

- Discharge Port Diameter 2″ MNPT

Permanent link to this article: https://etscompany.com/wordpress/2011/08/26/storms-coming-to-the-east-cost-be-ready-with-a-water-pump-from-ets-co/

Aug 25 2011

Don’t be left in the dark… Get your portable generator TODAY!

This Portable Generator Features:

- 3100 Watts max AC output, 2800 watts continuous AC output

- 6.5 HP recoil Start PowerEase OHV gasoline engine 74 decibels with engine oil alert

- 120/240Volt

- Auto Voltage Regulator

- 4 Gallon fuel tank capacity

- Run time Approximately 11 hours @ 50% load

- Heavy-duty frame powder coated steel tubing

- Receptacles – (1) 120V duplex, (1) 240V twist lock receptacles

- (3) Circuit breakers (1)10 Amp (1) 20 Amp (1) 30 Amp

- CSA Approved Genpack

- Carb Approved

- 108 lbs.

Sale Price: $598.00 Click here to purchase this portable generator before your power goes out.

Permanent link to this article: https://etscompany.com/wordpress/2011/08/25/dont-be-left-in-the-dark-get-your-portable-generator-today/

Aug 25 2011

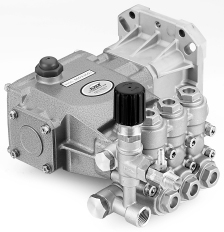

CAT 66DX35G1I Pressure Washer Pump

![]() CAT 66DX35G1I Pressure Washer Pump 3.5GPM 4000PSI 1″ GAS W/UNL.

CAT 66DX35G1I Pressure Washer Pump 3.5GPM 4000PSI 1″ GAS W/UNL.

List Price: $1,084.66

Our Price: $834.65 Click to order this CAT Pump.

Direct-Drive

Plunger Pump

Parts Breakdown for this CAT Pressure Washer Pump Click Here.

Repair Manual for the CAT 66DX35G1I Click Here.

The CAT Pressure Washer Pump 66DX35G1I Features are:

- Triplex plunger design provides a smooth liquid flow.

- Special concentric, high-density, polished, solid

- ceramic plungers provide a true wear surface and extended seal life.

- Compact flange mount permits easy, direct mounting

- to most gas engines. Modular Regulating Unloader with built-in by-pass is standard for safety and pressure setting.

- Fixed Chemical Injector is standard and mounts directly onto Unloader to provide cleaning flexibility.

![]()

This CAT 66DX35G1I Pressure Washer Pumps Specifications are:

- Flow ……………………………………………..3.5 GPM (13.2 L/M)

- Pressure Range ……………………100 to 4000 PSI (7 to 275 BAR)

- Stroke………………………………………………..0.394″ (10 mm)

List Price: $1,084.66

Our Price: $834.65 Click to order this CAT Pump.

Permanent link to this article: https://etscompany.com/wordpress/2011/08/25/cat-66dx35g1i-pressure-washer-pump/

Aug 24 2011

Annovi Reverberi RS Series Pressure Washer Pumps

Annovi Reverberi RS Series Pressure Washer Pumps – The Annovi Reverberi RSV series are designed to direct drive on gasoline engines ranging from 5 – 13 h.p. Intended use for medium to heavy tasks; this triplex plunger pump features the latest in design and technology. Life tested over 500 hours at maximum performance of 4 gpm at 4,000 psi. The Annovi Reverberi RSV series Pressure Washer Pump features a compact and efficient intergraded unloader valve and fixed chemical injector. The RSV is a result of our combined 60 years of pumps building experience and expertise. Flows: 2.5 to 4 GPM Pressure to: 4000 PSI Speeds: 3400 rpm Shaft Styles: Hollow Shaft 3/4″ and 1″.

| RSV2.5G25D-F25 Annovi reverberi Pressure Washer Pump | RSV3G25D-F25 Annovi reverberi Pressure Washer Pump | ||||

|

|

||||

|

|

||||

| RSV2.5G25D-F25 AR (Annovi Reverberi) Pump 2.5 GPM @ 2500 PSI, 3/4″ Hollow Shaft – Great for most 5 and 5-1/2 HP Gas Engines with a straight shaft! | RSV3G25D-F25 AR (Annovi Reverberi) Pump 3 GPM @ 2500 PSI, 3/4″ Hollow Shaft – Great for most 5 and 5-1/2 HP Gas Engines with a straight shaft! | ||||

| RSV3G35D-F40 3 GPM @ 3500 PSI | RSV4G30D-F40 4 GPM @ 3000 PSI | ||||

|

|

||||

|

|

||||

| RSV3G35D-F40 AR (Annovi Reverberi) Pump 3 GPM @ 3500 PSI, 1″ Hollow Shaft – Great for most 6 to 9 HP Gas Engines with a straight shaft! | RSV4G30D-F40 AR (Annovi Reverberi) Pump 4 GPM @ 3000 PSI, 1″ Hollow Shaft – Great for most 6 to 9 HP Gas Engines with a straight shaft! | ||||

| RSV4G40D-F40 Annovi reverberi Pressure Washer Pump | RSV3.5G35D-F40 Annovi reverberi Pressure Washer Pump | ||||

|

|

||||

|

|

||||

| RSV4G40D-F40 AR (Annovi Reverberi) Pump 4 GPM @ 4000 PSI, 1″ Hollow Shaft – Great for most 6 to 9 HP Gas Engines with a straight shaft! | RSV3.5G35D-F40 AR (Annovi Reverberi) Pump 3.5 GPM @ 3500 PSI, 1″ Hollow Shaft – Great for most 6 to 9 HP Gas Engines with a straight shaft! | ||||

Permanent link to this article: https://etscompany.com/wordpress/2011/08/24/annovi-reverberi-rs-series-pressure-washer-pumps/

Aug 23 2011

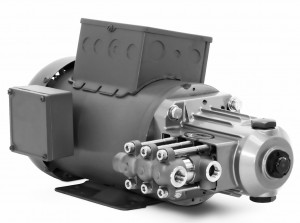

CAT Pressure Washer Pump 2SF10SEEL

CAT Stainless Steel Direct-Drive Plunger Pressure Washer Pump

Our Price: $1,179.00 Click to order the CAT 2SF10SEEL Pressure Washer Pump or

Call 1-877-824-7763 for a better price

CAT 2SF10SEEL Pressure Washer Pump FEATURES:

•Rugged 316SS design engineered for SWRO high duty cycles.

•High efficiency triplex design with unique spring loaded inlet valves and flow through plungers for smooth low pulsation flow.

•56C direct-drive 50/60 Hz motor satisfies international power requirements.

•Compact motor-pump units provide the smallest possible footprint for challenging spaces.

COMMON SPECIFICATIONS of the 2SF10SEEL CAT Pressure Washer Pump are:

Inlet Pressure Range……………….Flooded to 60 psi (Flooded to 4 bar)

Shaft Diameter…………………………………………..5/8” (15.9 mm)

RPM………………………………………………….1725 rpm (1725 rpm)

Bore………………………………………………………0.709” (18 mm)

Bore (2SF42SEEL Only)…………………………..0.787” (20 mm)

Maximum Liquid Temperature…………………..160°F (70°C)

Above 130°F call CAT PUMPS for inlet conditions and elastomer recommendations.

Crankcase Capacity………………………………12.0 oz. (0.36 l)

Inlet Port (1)………………………………………3/8” NPTF (3/8” NPTF)

Discharge Ports (2)…………………………….3/8” NPTF (3/8” NPTF)

By-Pass Return Port (1)……………………..1/4” NPTF (1/4” NPTF)

Weight (Pump Only)……………………………….8.9 lbs. (4 kg)

Dimensions (Pump Only)………………6.8 x 8.7 x 5.2” (173 x 221 x 133 mm)

Flow (60 Hz-1725 rpm)……………………………….1.0 gpm (3.8 l/m)

Flow (50 Hz-1450 rpm)……………………………..0.84 gpm (3.1l/m)

Discharge Pressure Range…………………..100-1200 psi (7-85 bar)

Stroke………………………………………………………..0.122” (3.1 mm)

CAT 2SF10SEEL Pump Breakdown pdf CLICK HERE.

2SF10SEEL CAT Pressure Washer Pump Repair Manual Click Here.

Permanent link to this article: https://etscompany.com/wordpress/2011/08/23/cat-pressure-washer-pump-2sf10seel/

Aug 22 2011

Annovi Reverberi SXW Series Pumps

Annovi Reverberi SXW Series Pressure Washer Pumps – Plunger Pumps are designed for high-pressure industrial washing applications. These Annovi Reverberi pressure washer pumps are constructed of die-cast bodies and feature a forged brass head with a bayonet style sight glass in the rear and side covers. Internal components include special solid ceramic plungers for long life and durability. Precision cast cooling fins are anodized for maximum heat dissipation. Oversized premium tapered roller bearings and the precision supports assure proper shaft alignment and maximum life. Valve cages of special designed Ultra-Form provide positive seating and extended life. Two-piece connecting rods are a special alloy aluminum-based material oversized for strength and load disbursement. These pumps are designed for gearbox, belt drive, or flex coupled systems, with a 24mm solid crankshaft. Flows: 3.96 to 7 GPM Pressure to: 5100 PSI Speeds: 1450, 1750 rpm Shaft Styles: Solid Shaft 24mm

| SXW15.35 Annovi reverberi Pressure Washer Pump | SXW21.35 Annovi reverberi Pressure Washer Pump | ||||

|

|

||||

|

|

||||

| SXW15.35 AR (Annovi Reverberi) Pump 3.96 GPM @ 5100 PSI | SXW21.35 AR (Annovi Reverberi) Pump 5.55 GPM @ 5100 PSI | ||||

| SXWA4G50 Annovi reverberi Pressure Washer Pump | SXWA5.5G50 Annovi reverberi Pressure Washer Pump | ||||

|

|

||||

|

|

||||

| SXWA4G50 AR (Annovi Reverberi) Pump 4 GPM @ 5000 PSI | SXWA5.5G50 AR (Annovi Reverberi) Pump 5.5 GPM @ 5000 PSI | ||||

| SXWA7G50 Annovi reverberi Pressure Washer Pump |  |

||||

|

|||||

|

|||||

| SXWA7G50 AR (Annovi Reverberi) Pump 7 GPM @ 5000 PSI | |||||

Permanent link to this article: https://etscompany.com/wordpress/2011/08/22/annovi-reverberi-sxw-series-pumps/

Aug 12 2011

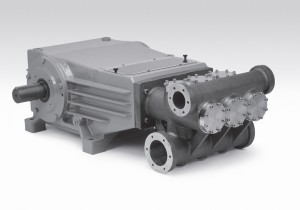

CAT Pressure Washer Pump 2520

CAT Pressure Washer 25 Frame Piston Pump:

Standard Brass Models 1520,2520

Stainless Steel Models 1521,2521

Pulse Pump Manifold Models 1525,2525

Hi-Temp Model 2520C

CAT Pressure Washer Pump 2520 FEATURES:

•Superior Design

•Triplex Uniflow design provides continuous forward liquid flow for smooth operation.

•Wetted cups and floating pistons are lubricated and cooled by pumped liquid for long cup life.

•Mechanically actuated inlet valves give strong lift and easy prime.

•304 stainless steel flat valve design offers positive seating and greater suction capabilities.

•Oil bath crankcase assures optimum lubrication.

Quality Materials used in the 2520 CAT Pressure Washer Pump are:

•Cylinder and sleeve wear surfaces are hard chrome plated 304 stainless steel for maximum durability and abrasion resistance.

•Chrome plated, brass manifolds and optional stainless steel manifolds are strong and corrosion resistant.

•Special high strength TNM connecting rods offer superior bearing quality strength.

•Chrome-moly crankshaft gives unmatched strength and surface hardness.

•Oversized crankshaft bearings with greater loading capacity mean longer bearing life.

The CAT 2520 Pressure Washer Pump has Easy Maintenance:

•Stepped stainless steel piston rod and with chrome-plated, stainless steel sleeve allows easy replacement from front of pump.

•All wet-end wear parts are easily serviced without entering crankcase, requiring less time and effort.

•Wear parts are available in convenient kits.

CAT Pressure Washer MODEL 2520, 2521, 2525 and 2520C Specifications:

Flow ……………………………………………………………..25 GPM (95 L/M)

Pressure Range ……………………………………100 to 800 PSI (7 to 55 BAR)

RPM……………………………………………………………772 RPM (772 RPM)

Bore ………………………………………………………………..1.490″ (38 mm)

Inlet Pressure Range ………………………Flooded to +40 PSI (Flooded to +2.8 BAR)

Maximum Liquid Temperature……………………………..210°F (98°C)

Flushing Ports (2) ………………………………………..1/4″ NPTF (1/4″ NPTF)

Dimensions ………………………………………21.42 x 15.04 x 7.8″ (544 x 382 x 198 mm)

Stroke ……………………………………………………………..1.417″ (36 mm)

Inlet Pressure Range ……………………………–8.5 to +40 PSI (–0.6 to +2.8 BAR)

Crankcase Capacity …………………………………………..84 oz. (2.5 L)

Maximum Liquid Temperature……………………………..160°F (71°C)

Above 130°F call CAT PUMPS for inlet conditions and elastomer recommendations.

Inlet Ports (1)……………………………………………1-1/4″ NPTF (1-1/4″ NPTF)

Discharge Ports (3) ………………………………………..1″ NPTF (1″ NPTF)

Pulley Mounting ………………………………………….Either side (Either side)

Shaft Diameters ………………………………………………..1.181″ (30 mm)

Weight ………………………………………………………….69.3 lbs. (31.5 kg)

Dimensions…………………………………….21.62 x 15.04 x 7.8″ (549.15 x 382 x 198 mm)

CAT Pressure Washer Pump Breakdown for 2520 Click Here.

CAT 2520 Pressure Washer Pump Repair Manual Click Here.

Call 1-877-824-7763 {Smart Phones Click to Call} for pricing and availability on this CAT Pressure Washer Pump: 2520

Permanent link to this article: https://etscompany.com/wordpress/2011/08/12/cat-pressure-washer-pump-2520/

Aug 12 2011

CAT Pressure Washer Pump 152R060

CAT Pressure Washer 150 Frame R-Series, Duplex Stainless Steel, Reciprocating Process Pumps

Standard and C-Flushed Models

152R060,152R060C

152R080,152R080C

152R100,152R100C

Call 1-877-824-7763 {Smart Phones Click to Call} for pricing and availability on this CAT Pressure Washer Pump: 152R060

CAT Pressure Washer pump 152R060 FEATURES:

•Triplex design delivers high efficiency and low pulsation.

•Durable dual V-Packings are lubricated and cooled by pumped liquid.

•Pre-Set Lo-Pressure Seals provide secondary protection against external leaks and require no packing adjustment.

•Special high density, polished, concentric plungers provide a true wear surface and extended seal life.

•Specially formulated Seals and V-Packings offer unmatched perfor-mance and extended seal life.

•Ceramic plungers, Seals and V-Packings are serviceable from the top of the crankcase permitting easy in-field servicing.

COMMON SPECIFICATIONS for the CaT 152R060 Pressure Washer Pump:

Inlet Pressure Range……………….Flooded to 50 psi (Flooded to 3.5 bar)

Minimum RPM……………………………………………75 rpm (75 min-1)

Stroke………………………………………………………………5.91” (150 mm)

Crankcase Capacity………………………………..22.4 Gals (85 l)

Lubrication…………………………………………………..Splash (splash)

Maximum Liquid Temperature………………….140°F (60°C)

Inlet Ports (2) (Flange Required)……………………6.0” (150 mm)

Discharge Ports (2) (Flange Required)………….4.0” (100 mm)

Shaft Diameter…………………………………………….3.937” (100 mm)

Weight……………………………………………………..3087 Lbs (1400 kg)

Dimensions………………………68.11 x 42.13 x 22.05” (1730 x 1070 x 560 mm)

Specific SPECIFICATIONS for CAT Pressure Washer Pump MODEL 152R060 STANDARD API:

Flow…………………………….. 115 gpm (435 l/m) 86 gpm (326 l/m)

Barrels Per Day (U.S., Petroleum) — — 2948 bbl/d —

Pressure Range*………… 100 to 1200psi (7 to 85 bar) 100 to 1200 psi (7 to 85 bar)

Maximum RPM………….. 360 rpm (360 min-1) 270 rpm (270 min-1)

Bore…………………………….. 2.375” (60.3 mm) 2.375” (60.3 mm)

CAT 152R060 Pump Breakdown Click Here.

CAT 152R060 Pump Service Manual Click Here.

Permanent link to this article: https://etscompany.com/wordpress/2011/08/12/cat-pressure-washer-pump-152r060/