The KE Series Pressure Washer Pumps from General Pumps replaces all old EK Series Pressure Washer Pumps from General Pumps.

KE Pressure Washer Pump from General Pumps

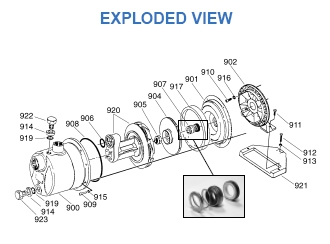

KE Series Pressure Washer Pumps from General Pumps FEATURES:

• A “New Generation” Pump

• Triplex Plunger Pump, available in 5 flows

• Patent-pending, symmetrical power end design featuring top and bottom mounting holes allowing for easy left to right shaft conversion

• Low-high pressure packing design with integrated cooling system

• High volumetric efficiency suction/delivery valves featuring new spherical design of sealing areas

• Splash lubrication

• SAE-B hydraulic drive bell housing and flexible couplers available

KE series pressure washer pump from General Pumps

KE Series Pressure Washer Pumps from General Pumps MATERIALS:

• High resistance light alloy die cast aluminum crankcase

• 420 Stainless steel manifold, nickel treated

• Taper roller bearings

• Special antifriction, forged, light alloy connecting rods

• Forged alloy steel crankshaft, hardened, tempered and nitrited

• Cast iron piston guide, nickel treated

• Solid ceramic plungers

• Stainless steel valves

• Pumps are also available with 316 SS packing components.

These models use prefix “KEN”

KE series pressure washer pump from General Pumps

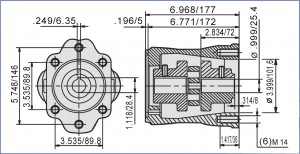

KE Series Pressure Washer Pumps from General Pumps COMMON SPECIFICATIONS:

• Maximum Inlet Pressure: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 PSI

• Maximum Fluid Temperature: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . *140° F

• Inlet Port Thread: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1″ NPT-F

• Discharge Port Thread: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2″ NPT-F

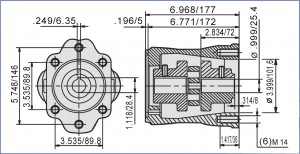

• Shaft Diameter: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.181″/30 mm

• Stroke: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.9055″/23 mm

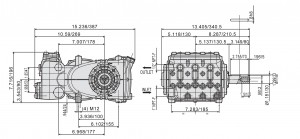

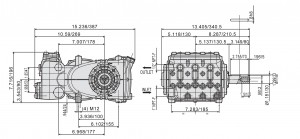

• Pump Dimensions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15.2″ x 13.4″ x 7.7″

• Crankcase Oil Capacity: . . . . . . . . . . . . . . . . . . . . . . . . . . 67.63 oz. (2 liters)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (use GP Series 220 Oil)

• Shipping Weight: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88 lbs./40 kg

*Please consult technical guide or GP Sales Representative for

Temperature/Inlet Pressure Information.

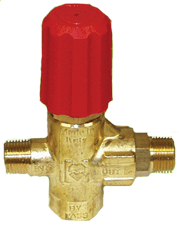

KE Series Pressure Washer Pumps from General Pumps PUMP OPTIONS:

• “F” version features flushing option

• “G” version suitable for pumping high-temperature glycols (up to 140o F)

• “N” version available with 316 Stainless Steel packing components, maximum water

temperature 185oF

• SAE-J 744-B hydraulic drive bell housing and flexible couplers available.

Click the link to see all our KE Series Pressure Washer Pumps from General Pumps at ETS Company.